BDCW ULTIMATE Skid Plates continue to be the top choice for expert riders, proving its worth in the most rigorous conditions and terrain worldwide. Think you don’t need this much protection? Think again. It’s while learning to master big bike skills, both on pavement and off-road, that carnage happens. Rocks get kicked up, bikes get dropped and hung up, curbs get in the way, and scrapes and spills are just part of the adventure. And the ULTIMATE Skid Plate is designed to take all of the abuse—and more.

DESIGN NOTES

Black Dog Cycle Works has once again designed an Ultimate Skid Plate for the new Aprilia Tuareg 660. We recognize any product is a compromise - manufacturers have to balance key features, materials selection, ease of installation, ease of removal for maintenance, development costs, production costs, related shipping costs to the consumer as well as where the product is made. Based on our 16 years of development experience, we feel we have struck an ideal balance with our new Ultimate Skid Plate for the Aprilia Tuareg 660.

Like many adventure bikes these days, the Tuareg does not have a cradle frame to attach the skid plate, so we had to get creative with the mounting points. We were able to pick up on the frame at the rear of the skid plate as well as tie into the crash bar mounting points to provide extremely strong support for the skid plate. In addition the skid plate removes with six bolts for easy maintenance access.

We also made the skid plate compatible with the OEM center stand and Hepco Becker upper crash bars (others have not been tested yet).

Some riders may say "my 660 already has a skid plate on it from the factory" - our only question is how much faith do you want to put in that 'aluminum foil" stock skid plate to prevent you from damaging your motor and having to walk out of the backcountry? With the Black Dog Skid Plate, you can ride those remote areas we all love so much with confidence.

Another key aspect we focused on was to maximize ground clearance while still providing a "crush zone" between the skid plate and key components such as the header pipe. The 3/16" (4.76mm) 5052 Aluminum we use in our skid plate will give a bit on impact, lessening the force transmitted to the mounting points as well as being less likely to crack, unlike the harder materials used by some of our competitors.

Please see our "Nuts, Bolts and Benefits" below for more details

We have two different fitments based on the crash bars being used on the bike:

FITMENT A: No Crash Bars, Hepco Becker crash bars (recommended) or other crash bars that mount against the frame of the bike.

FITMENT B: OEM Crash bars. This style crash bar inserts into the frame of the bike or our mounts for this fitment are designed to accommodate that by mounting outside the crash bar mounting bung.

FITMENT

This skid plate fits the following models:

- APRILIA TUAREG 660 (2023+)

COMPATIBILITY

- Compatible with Aprilia OEM Center Stand

- See above fitment explanation for crash bar compatibilty.

NUTS, BOLTS & BENEFITS

Comprehensive Engine Coverage

"Sized Right" to cover keep major components safe such as the engine block, header pipes and catalytic converter.

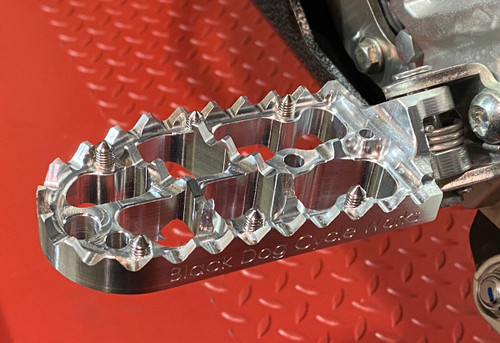

Flush Mount Hardware

We never use hardware that protrudes from the skid plate in highly probably impact areas (like the bottom!!). The flush mount hardware we use is MUCH less prone to catch on obstacles or get damaged.

Optimized Ground Clearance and Coverage

Sleek, low profile design optimizes the balance between maintaining crush zones, providing excellent ground clearance and reducing the overall profile to minimize impacts

EASY installation

15 minutes max once you remove the stock tin foil "skid plate"

6 bolts to remove for Maintenance

EASY! We like easy! We work on our own bikes, so why would be make this difficult? The two mounting brackets do not need to be removed for maintenance nor do lower crash bars you may have on the bike.

The RIGHT Material = More Protection—3/16-inch (4.76mm) of 5052 Aluminum

You get what you pay for. And we found the optimal material to protect, perform, and last. In fact, it could outlive your bike. The grade of aluminum we selected is designed to ABSORB impacts, not transfer the force to the mounting points on the bike.

Smooth Bottom for Clearing Obstacles

No holes to snag on rocks or branches. This plate glides on its own˜right up over most obstacles without bolts, rubber sliders or rivets to catch or break.

Flat Bottom is maintenance friendly

Need to lift your bike for maintenance chores and changing tires, no problem. Our design can take it.

Rubber Shok Blok

Placed between the engine and skid plate to help absorb and disburse the energy from large impacts.

Powder AND Clear Coated

Looks great and takes the punishment that anodized finishes can’t.

Looks Badass on Every Bike

Not that it matters when it’s covered in mud.

Cheap Insurance

Considering the costs of expensive repairs or “extractions” from the backcountry, it’s a bargain!

Made in the U.S.

No bones about it, we manufacture all of our Black Dog products right here in the U.S. It is extremely important to us. We have world class manufacturers in our own back yard and we intend to use them. Purchasing this product is a opportunity to support a small family business and support American Workers and the U.S. economy, not some random large corporation based overseas. Besides, the Black Dog needs to eat too!

WHAT RIDERS ARE BARKING ABOUT:

Hi Folks. Heading outbfor another adventure on my Aprilia Tuareg. Changed oil before I left and myst say your design for dropping the skid plate is fantastic. 4 bolts and that was it! I was hesitant to drop the kind of cash it took to buy this but the old adage “you get what you pay for” once again hold true. Riding with 4 buddies this weekend and will try and sell some more skid plates for you! Thanks

Kim Marks - Tuareg 660

MADE IN THE USA